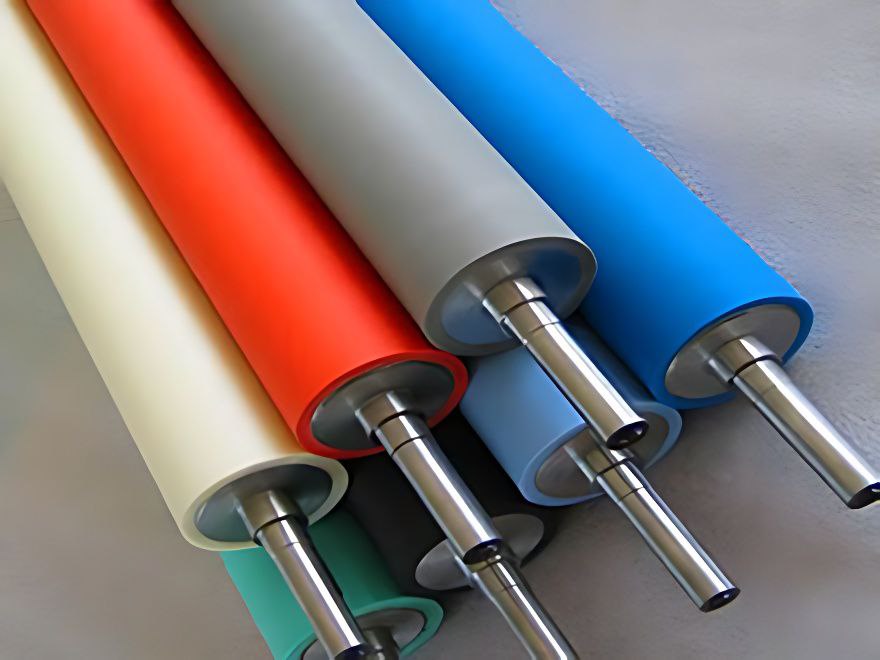

Elevate your industrial and manufacturing processes with our premium rubber rolls. Crafted from top-grade rubber materials, our rubber rolls are designed to meet the demands of various applications. Here’s what makes our rubber rolls stand out:

- Material: Rubber rolls are typically made from high-quality rubber compounds, including natural rubber, synthetic rubber (such as neoprene or silicone), or a blend of various rubber types. The choice of rubber material depends on the specific application and the desired properties.

- Cylindrical Shape: Rubber rolls are cylindrical, with varying diameters and lengths to suit different requirements.

- Applications: Rubber rolls have a wide range of applications, including but not limited to:

- Printing: Rubber rolls are used in printing presses to transfer ink from plates to paper or other surfaces.

- Conveyors: They can be used in material handling systems to move items along a production line.

- Laminating: Rubber rolls are essential in the laminating process to bond materials together.

- Industrial Machinery: Many industrial machines use rubber rolls for embossing and embrittlement.

- Hardness: Rubber rolls can be manufactured with different hardness levels, measured using the Shore durometer scale. The hardness affects their grip, wear resistance, and other performance characteristics.

- Surface Texture: The surface of rubber rolls can vary, with options like smooth, grooved, or patterned surfaces, depending on the application.

- Customization: Rubber rolls can be customized to meet specific requirements, including size, material, hardness, and surface texture.

- Durability: Rubber rolls are known for their durability and resistance to wear, making them suitable for repetitive and demanding tasks.

- Maintenance: Proper maintenance, such as cleaning and occasional re-covering with fresh rubber, can extend the lifespan of rubber rolls.

- Cost-Effective: Rubber rolls are often a cost-effective solution for various industrial processes due to their longevity and versatility.

- Exceptional Material: Our rubber rolls are crafted from a choice of top-quality rubber compounds, ensuring durability and high performance.

- Versatile Cylindrical Design: These cylindrical rubber rolls come in various diameters and lengths to suit your specific needs.

- Wide Range of Applications: From printing and material handling to laminating and industrial machinery, our rubber rolls are adaptable to various industries and processes.

- Customization: We offer customization options to tailor the rubber rolls to your unique requirements, including size, material, hardness, and surface texture.

- Durable and Long-Lasting: Built for the long haul, our rubber rolls are resistant to wear and designed for longevity.

- Maintenance and Cost-Effective: Regular maintenance and occasional re-covering with fresh rubber ensure continued performance, making our rubber rolls a cost-effective choice.

Benefits:

- Enhance productivity and efficiency in your operations.

- Improve the quality and consistency of your output.

- Reduce downtime and maintenance costs with durable rubber rolls.

- Tailor the rolls to match your specific industry needs.

Application Examples:

- Printing: Achieve precise ink transfer in printing presses.

- Material Handling: Effortlessly move items along your production line.

- Laminating: Bond materials securely together.

- Industrial Machinery: Support various processes, such as embossing and embrittlement.

Invest in the quality and versatility of our rubber rolls to optimize your manufacturing processes. Trust in the durability and performance of our products. Contact us today to discuss your requirements and secure the rubber rolls that match your industry needs.

of core preparation is to expose the cores to steam at about 150°C for several hours. However this is not performed by many manufacturers, and due to economic reasons, this removes the anticorrosive materials applied on new cores, which are normally roughly machined. Although light metal cores are not protected by an anti-corrosive agent Their surfaces are slightly more porous than steel cores and should also be cleaned with steam. Any deeply cut grooves should be machined off the core before the steam treatment. This is to avoid the increased risk of trapping air between the core and the rubber covering when the latter is applied. In the case of used metal rolls, the old rubber covers are removed on a lathe or, less frequently, by burning off.

After this preliminary cleaning, the cores are sandblasted to produce a virgin metal surface that is free from rust and scale and also to increase the surface area for better bonding. If the first step of steam heating is skipped, sandblasting ensures good bonding between metal and rubber.

Finally,

the cores are cleaned with a solvent to remove any trace of oil and grease.

The prepared core is applied with a bonding agent as soon as possible, to avoid re-oxidation of the surfaces.

In the manufacture of rolls. Good rubber-to-metal bonding is ensured by two methods: chemical bonding agents and the use of an ebonite base layer.

Chemical bonding

agents offer short curing times (unlike ebonite) and give high adhesion values even at elevated temperatures (contrary to ebonite bonding. Which begins to soften at a relatively low temperature: ~ 70-80°C). Chemical bonding agents are, however, somewhat sensitive to mechanical influences. If rolls, particularly those having a relatively thick rubber cover, are subjected to dynamic stresses. The increasing shear forces may cause the cover to break loose with time.

Ebonite tie stock is sometimes preferred, especially when the rolls have a thick rubber covering and are subjected to heavy dynamic stresses. Nowadays small and medium-sized rolls are almost exclusively produced with chemical bonding agents. Ebonite offers very high separation strength and the rubber covering undergoes little deflection. Since up to a quarter of it may consist of ebonite, which has little tendency to be deformed.